On the global business stage, the construction of automated three-dimensional warehouse projects has become a key measure to improve the logistics efficiency and competitiveness of enterprises. Through its advantages of efficiency, precision, and space saving, it has become the first choice for many enterprises.

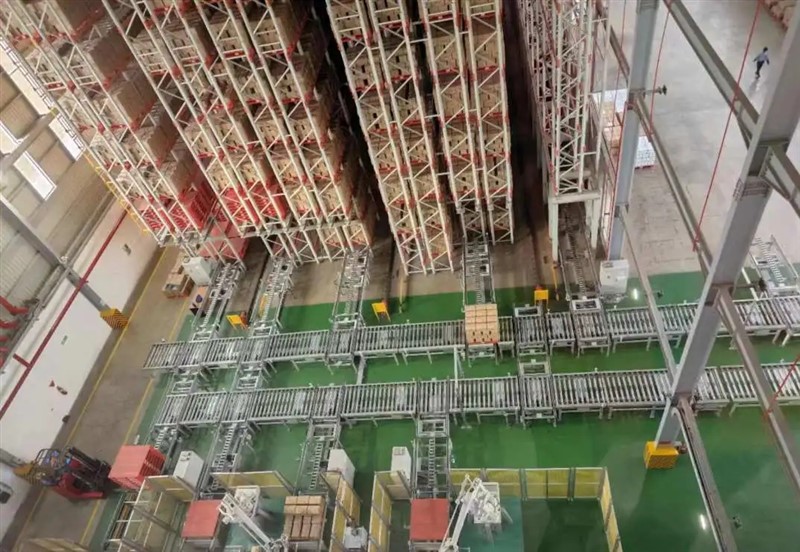

Recently, a stacker crane three-dimensional warehouse project located in Southeast Asia has successfully completed acceptance, laying a solid foundation for expanding more projects in the future.

Project Overview

The project is located in a certain region of Southeast Asia, and the entire process from planning to construction strictly follows international standards and industry best practices.

Mastercard, with years of technical accumulation and industry experience, fully leverages the project characteristics of stacker crane three-dimensional warehouses to create a dense storage system with high storage density, efficient inbound and outbound, and rigorous logical algorithms for customers.

Solution

The stacker crane three-dimensional warehouse project effectively coordinates the Mastercard software system, stacker crane, mother and child vehicle, elevator, shelf, RGV and other systems to complete the massive storage and efficient operation of the three-dimensional warehouse.

Shelf system

The shelving system uses high-strength and high load-bearing materials to ensure its long-term reliability, with a stable structure and reasonable layout, maximizing the use of warehouse space.

At the same time, by optimizing the shelf spacing, the density of goods storage has been increased while ensuring the storage of goods.

conveying system

The stacker crane can operate efficiently in the vertical space of the three-dimensional warehouse, greatly increasing the storage space. And customized design based on the layout of the warehouse and the characteristics of the goods, to meet the storage needs of different types and sizes of goods.

It quickly and accurately places goods in designated shelf positions with a precision of up to millimeters. Thanks to advanced sensor technology and precise control systems, the accuracy and stability of every operation are ensured.

The automated conveyor line runs smoothly and can quickly and accurately transport goods from the storage port to the designated storage location, and then retrieve them from the storage location and deliver them to the outbound port. And it has automatic recognition and error correction functions, even under high load operation, there are very few faults and deviations.

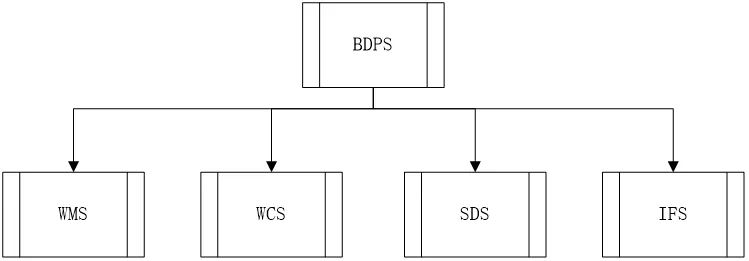

software system

The intelligent control system is one of the core highlights of this three-dimensional warehouse, which achieves real-time monitoring, inventory management, and job scheduling of goods in the warehouse through advanced software algorithms.

Integrate WMS, WCS, SDS, and IFS systems to eliminate information silos between different systems and achieve seamless flow and sharing of data.

Project acceptance

At the acceptance site, the expert group conducted a detailed inspection and evaluation of every aspect of the project. From performance testing of devices to stability verification of systems, from inspection of security measures to testing of environmental indicators, every step is strictly carried out according to predetermined standards.

In the future, this three-dimensional warehouse project will provide customers with more efficient and reliable warehousing services. At the same time, it also provides useful reference and inspiration for the construction of logistics facilities in other countries and regions.

On the global business stage, the construction of automated three-dimensional warehouse projects has become a key measure to improve the logistics efficiency and competitiveness of enterprises. Through its advantages of efficiency, precision, and space saving, it has become the first choice for many enterprises.

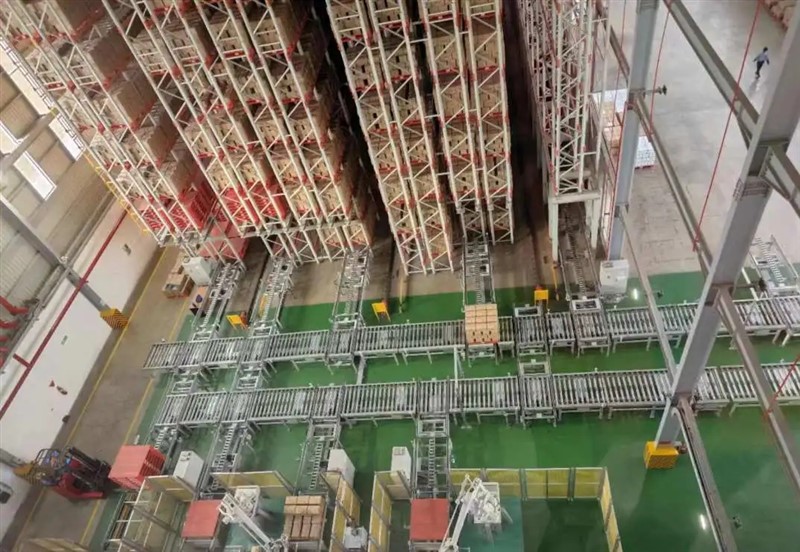

Recently, a stacker crane three-dimensional warehouse project located in Southeast Asia has successfully completed acceptance, laying a solid foundation for expanding more projects in the future.

Project Overview

The project is located in a certain region of Southeast Asia, and the entire process from planning to construction strictly follows international standards and industry best practices.

Mastercard, with years of technical accumulation and industry experience, fully leverages the project characteristics of stacker crane three-dimensional warehouses to create a dense storage system with high storage density, efficient inbound and outbound, and rigorous logical algorithms for customers.

Solution

The stacker crane three-dimensional warehouse project effectively coordinates the Mastercard software system, stacker crane, mother and child vehicle, elevator, shelf, RGV and other systems to complete the massive storage and efficient operation of the three-dimensional warehouse.

Shelf system

The shelving system uses high-strength and high load-bearing materials to ensure its long-term reliability, with a stable structure and reasonable layout, maximizing the use of warehouse space.

At the same time, by optimizing the shelf spacing, the density of goods storage has been increased while ensuring the storage of goods.

conveying system

The stacker crane can operate efficiently in the vertical space of the three-dimensional warehouse, greatly increasing the storage space. And customized design based on the layout of the warehouse and the characteristics of the goods, to meet the storage needs of different types and sizes of goods.

It quickly and accurately places goods in designated shelf positions with a precision of up to millimeters. Thanks to advanced sensor technology and precise control systems, the accuracy and stability of every operation are ensured.

The automated conveyor line runs smoothly and can quickly and accurately transport goods from the storage port to the designated storage location, and then retrieve them from the storage location and deliver them to the outbound port. And it has automatic recognition and error correction functions, even under high load operation, there are very few faults and deviations.

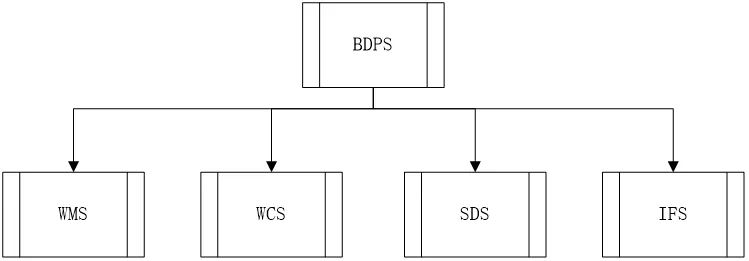

software system

The intelligent control system is one of the core highlights of this three-dimensional warehouse, which achieves real-time monitoring, inventory management, and job scheduling of goods in the warehouse through advanced software algorithms.

Integrate WMS, WCS, SDS, and IFS systems to eliminate information silos between different systems and achieve seamless flow and sharing of data.

Project acceptance

At the acceptance site, the expert group conducted a detailed inspection and evaluation of every aspect of the project. From performance testing of devices to stability verification of systems, from inspection of security measures to testing of environmental indicators, every step is strictly carried out according to predetermined standards.

In the future, this three-dimensional warehouse project will provide customers with more efficient and reliable warehousing services. At the same time, it also provides useful reference and inspiration for the construction of logistics facilities in other countries and regions.